Services

Kitting & Consolidation Support

At Univa, every project involves critical components such as Reducing costs, saving

time, improving productivity and mitigating risk. We aim to streamline your

production, purchasing, receiving and warehouse process with our kitting and

consolidation capabilities.

With such customizable Supply Chain Solutions,

you can eliminate expenses, address sustainability requirements, enhance focus on

your core competencies and stay competitive in the marketplace.

Custom & Integrated Solutions

With the current wave of global procurement, fuelled along with the sharp increase in the number of companies involved in the process of manufacturing, the market is facing a stark requirement of vendors that provide seamless end-to-end solutions, which is also necessary to reduce the cost involved in the manufacturing process. This is where Univa’s Custom & Integrated solutions help companies maintain their requirements with an end to end solutions.

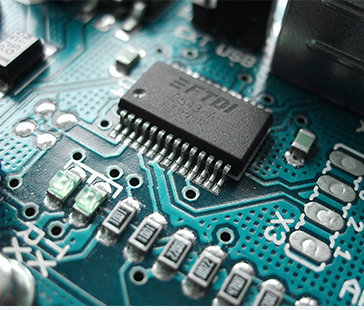

Shortage Of/Hard-to-find Components

Through the access of our broad reach of qualified suppliers, we make sure to

fulfill even the most difficult problems of component requirement. Our sourcing

teams are always placed on-the-go for product allocation with minimum lead times.

All our suppliers have been rated according to product conformance, timeliness, and

historic volume for careful identification and quick action.

With attributes

such as historic pricing data, current, and obsolete manufacturer cross-references,

and data sheets, our sourcing experts have a measurable advantage for sourcing and

negotiating to meet your price point expectations.

BOM

Handling the Bill of Materials is one of the most critical aspects of product

manufacturing. The BOM is the single most significant cost element for any product.

We help you to realize the factors responsible for reducing the cost factor in the

BOM.

We are an experienced company offering ultimate sourcing solutions to

businesses procuring raw materials or finished goods from developing or developed

economies. We implement our experience and knowledge into each and every aspect of

sourcing. Our professionals offer high-end BOM cost reduction services to our

esteemed clients, to help them achieve significant savings while improving their

overall sales as well as increase the profit margin.

With in-depth knowledge

and insight, we strive to offer real value for your money and ensure complete

client loyalty.

Time is of the utmost value as far as BOM cost reduction is

concerned. Products launched within the shortest time frame fail to materialize on

the cost optimization part.

The LLC (Low-Cost Country) sourcing part should

be properly evaluated to ensure low cost in materials used. Component suppliers may

decrease costs, but may not have passed on the benefits lack of suitable purchasing

trends arising due to acquisitions and mergers often hamper the cost reduction

aspect.

End-to-End Solutions

Our highly experienced team involves the utilization of a specific type of multi-stage process based on the flexibility level of each client, to meet to the exact required solution. Our Sourcing Team offers an in-depth analysis to figure out all the necessary cost reduction options available to reach the end requirement.

Our services include:

- Figuring out all the required alternatives available to facilitate reduced costing

- Trying to generate savings from every purchase consolidation

- Availing the benefits and applying the essential features of LLC sourcing

- Customized Reporting

- Repackaging / Relabelling

- Consolidated after sales services

Cross-Referencing

Selecting the right industry standard product for all your Electronic Components is

as easy as contacting us.

Our cross-reference database contains hundreds of

thousands of part number parameters. We can help you identify a “fit, form and

function” replacement or an equivalent alternative using some search criteria.

Our

Team follows the below Steps to find Cross Reference for your components

requirements.

- Search for your Part

- Cross to other Manufacturers

- Compare Several Options

- Access parametric data

- Export your selections

Value-added Supply Chain Services

At Univa, we continually invest in people, processes, and technologies to meet your complete supply chain needs. In our supply chain model, we address the below crucial areas that are necessary to build a practical solution:

Sourcing

Researching, identifying, validating and pricing products and managing multiple low-volume suppliers can be time-consuming and create inefficiencies in your business. With our manufacturer relationships and knowledge of the latest products and applications, we can help you reduce the time and resources spent on sourcing products.

Inventory Management

We understand that managing inventory is essential to maintaining operations and excellent customer service and has a direct impact on the profitability of your business. Managing high material lead times and maintaining proper inventory levels to ensure you have the right material ready when you need it can be costly and time-consuming, it can also hurt your schedule and budget if not appropriately managed.

Global Logistics

Every time products are moved or transported, the risk of project delays and added costs increase. Univa’ s global operations experience enables us to work with you to determine the most efficient methods for delivering products to help mitigate the risk of project delays.

Doing more with less is the goal of every company. Univa has the

experience and expertise in providing value-added services that complement your

warehousing, distribution and fulfillment functions.

Our customized

solutions support your business and help you improve efficiencies and customer

service.

Our value-added services include:

- Bonded Inventory

- On-line Procurement Services

- JIT (Just-In-Time) Deliveries

- Materials Management

- Off-Shore Sourcing

- Special Packaging (Military or Other)

- Private Labelling

- Shipping

- Component Sorting

Quality Assurance

Quality is an essential promise to our valued customers. Components we provide,

undergo a complete system of vendor verifying and management, standard quality

control, and testing procedures.

Univa follows standard practice for Quality

assurance that involves strict inward inspection. Whenever any part is received

within the facility, it is first met with datasheet verification and visual

inspection. A meticulous procedure is followed in case of the quality suspect and

is stores within a quarantine warehouse. A detailed inspection report is maintained

to check the same. For parts that match our inspection criteria are processed ahead

to facilitate fast and accurate logistic support.

Similarly, we make sure

that each part is shipped with proper detail and with an organized delivery

timeline that is backed by strong ERP support that helps Univa deliver the promised

quality to each of our esteemed customers.

Email Us to Know more

quote@univatech.com

For Technical Support call us at

+65

67428930